4DD was subcontracted to produce this striped bass for a Maryland sign company that eventually installed it in Chesapeake Beach MD. The fish was roughly 16ft long from nose to tail and around five feet tall.

We were first given a mounted striped bass. We made a 3D laser scan of the fish and produced a primitive fish model.

The primitive 3D Model was cleaned and modified to fit our design requirements. The model was then split into sections so that it could be routed on our CNC router.

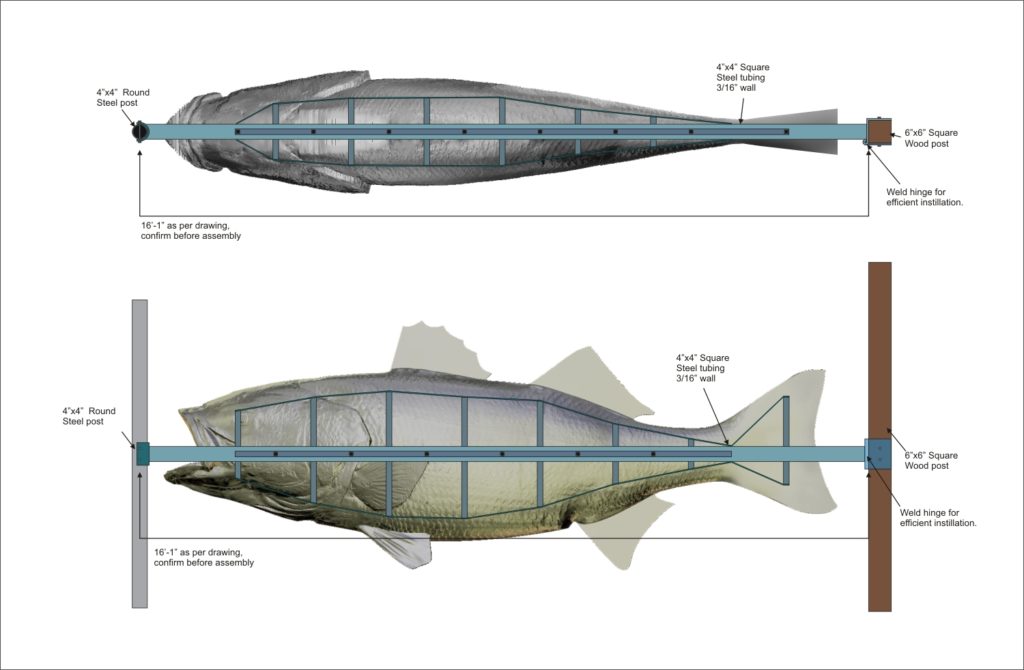

The armature design was incorporated into the model and submitted to the engineer for approval.

The split 3D Model pieces were routed using a CNC router and then cut free from their mounting using a CNC hotwire machine.

The cut out segments were then attached to each other and to the armature. Seams were patched and sanded and the unit was prepped for plasticoat.

The bass was coated in a polyurea coating that makes it both weather and impact resistant.

Once fully coated the bass is left to cure. After a few hours we begin the process of repairing any imperfections in the coating. Then we scuffed the surface to provide a tooth with which the paint can adhere.

Automotive paint was used to create the vibrant finish of the bass. A variety of colors and types of paint were used including a combination of pearlescent and metallic finishes.

Our fins were routed out of a PVC foam that is rigid yet still can be formed via thermo forming. The fins were attached directly to the armature to avoid any potential damage in high winds.

The gills were produced by cutting deep into the fish and painting in the texture of the ribbons.

We hired a Canadian Artist to glass blow the eyes for our striped bass. Each eye was the size of a dinner plate and around eight inches thick. The distortion in the glass gave the illusion that the eye followed you as you walked around the fish.

Our bass now resides in his new home welcoming viewers to the pier.